Plastics

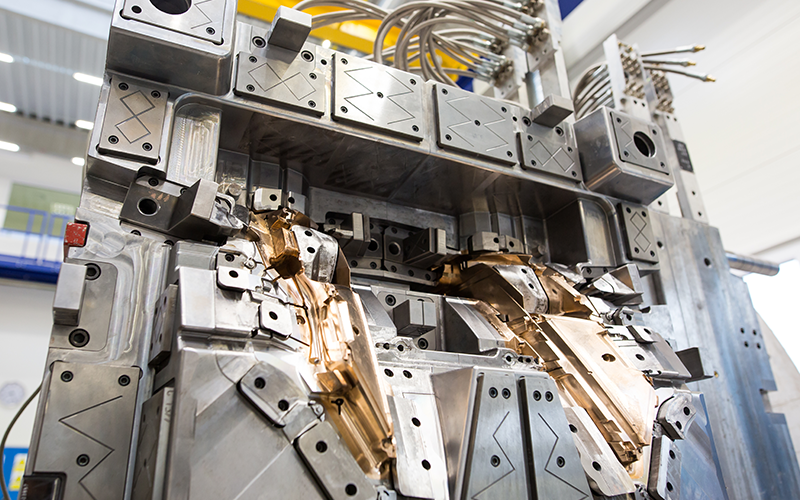

Dicronite® dry lubrication’s proven ability to increase flow and speed-up release, resulting from its high lubricity and precision tolerance (0.5 microns max.), coupled with low application temperature, high-temperature stability, and non flaking properties, make it the plastics industries key dry lubrication technology. ISO-10993 biocompatible for medical plastic molding. Companies including GE Plastics, Tyco, Bemis, Hayward Industries Plastics, and Univac use Dicronite® dry lubrication for:

- Reducing reject rates for a low draft or undercut parts such as caps and closures

- Reducing cycle times due to improved release

- Increasing uptime due to less wear on pins, bushings and mold surfaces

- As a co-deposit to improve the performance of TiN, CrN, CrC, and other surface treatments